Technology Kit

State-of the art solutions

At Co-mender we focus to provide our local partners with latest technologies that a specific market requires after conducting a full appraisal and evaluation of the needs. We tap into our knowledge, our experience and commitment to ensure our customers are getting the best solutions with high quality and at an affordable budget.

Solving today’s construction challenges

SUPPLY

We rely on high-quality products to support our developed solutions.

ENGINEERING

We reply on our international & Supplies experts and our experienced engineers to provide high end engineering services in support of our products.

SUPERVISION

With us our solutions providers have the chance to use our Co-menderAIR technology to supervise the installation/implementations of their solutions.

Join Our Team!

Welcome to QuakeWrap, Inc., the original innovator and developer of Fiber Reinforced Polymer (FRP) products for infrastructure repair and renewal. QuakeWrap and QuakeWrap, Inc. President/CEO Dr. Mo Ehsani have spent over 25 years pioneering advanced construction technologies utilizing FRP. QuakeWrap’s patented FRP products – including the innovative PileMedic® and PipeMedic® repair systems – are field-proven to rehabilitate, retrofit and strengthen assorted structures worldwide, with award-winning results.

QuakeWrap, Inc. is the original provider of fiber reinforced polymer (FRP) products and systems for infrastructure renewal, including the repair and strengthening of bridges, towers, tunnels, buildings, marine piles, seawalls and more.

Radcon Formula #7®

Established in Sydney in 1987, it was Radcrete Pacific’s mission to provide the constuction industry with a simpler and more effective way to waterproof concrete. Since then Radcon Formula #7® has successfully waterproofed and protected tens of millions of square meters of concrete worldwide. The products remarkable performance matched with straight forward application makes it the most efficient, economical and low risk choice for concrete waterproofing.

Radcon Formula #7® was first developed by Dr. A.W Smith in 1975, a scientist nominated for a Nobel Prize. Dr. Smith utilised his knowledge in the medical field to transform a basic silicate based material into one that could react in the matrix and cracks of concrete in a similar fashion to how cuts heal in human skin.

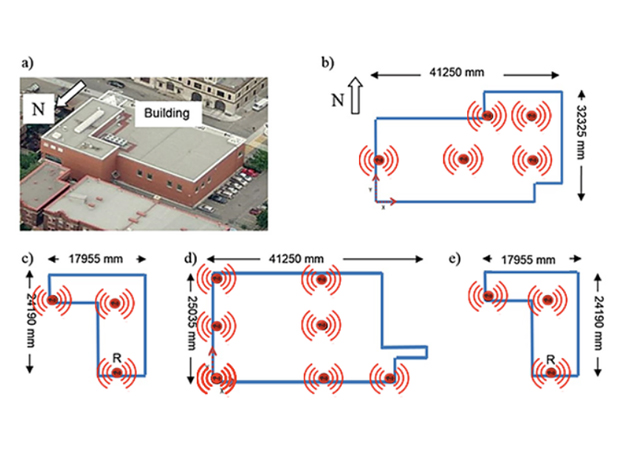

SENSOR POSITIONS

Highly sensitive, wireless vibration sensors are temporarily deployed on structural platforms to measure minute vibrations from micro-tremors, wind, traffic and human activity. These sensors are placed at carefully picked locations across the structure to deliver the most pertinent information. Sensing tests take a few hours and do not interrupt the building’s usual operations.

Captured data is analyzed with our advanced algorithms to generate the modal properties (natural frequencies, damping ratio and mode shapes) of the structure. These act as the structure’s baseline or signature, which is essential for monitoring the health and integrity of structures.

INNOVATIVE NONDESTRUCTIVE TESTING SOLUTIONS

FPrimeC Solutions is a technology startup in Oshawa, Canada. We develop innovative testing solutions for cost-effective and reliable assessment of infrastructure facilities. Research and development is at the core of our business and our identity as a technology company. At FPrimeC Solutions, we are committed to bringing leading technologies and making the next generation of testing solutions that help our customers succeed.

Our researchers and engineers then start studying potential solutions; we take these solutions, and turn them into exciting products that will shape the future of testing materials and structures.

What is concrete scanning?

Concrete scanning is the use of sensing technologies for the detection of subsurface utilities, construction flaws or deterioration defects. Especially, by using multiple nondestructive evaluation (NDE) technologies, scanning your concrete with CONSEN gives you an ability to:

- Locate underground utilities and conduits.

- Measure accurately the thickness of concrete walls, girders, or slabs.

- Obtain high-definition 2- and 3-D images of steel reinforcing bar arrangement in concrete.

- Identify the locations of post-tension cables and high-value hidden utilities before drilling or cutting concrete.

- Identify and map corrosion on concrete girders and slabs

- Obtain high-definition 2- and 3-D images of concrete delaminations, voids and other defects.

Gemite Systems

Think Globally – Act Locally

Our Technical Team draws upon extensive global resources and knowledge to quickly find innovative solutions to fit your needs. This enables Gemite to resolve customer challenges and tailor our products and services to the specific culture, tradition, technical standards, and engineering practices of the given region.

- Waterproofing – Above Ground & Underground

- Concrete Restoration

- Walls – EIFS, Plaster & Coatings

- Chemical & Corrosion Protection

- Floor – Toppings, Traffic Surfaces & Coatings

- Structural Strengthening

- Non-Destructive Diagnostics

Hummer 3D animation operation

Hummer high-end reinforcement material manufacturing expertsuse the quality to lay the foundation of the industry, using products to build industry reputation

Hummer’s R&D team and 5 German electronic

intelligent carbon fiber production lines, and the

introduction of aerospace composite technology and

nanotechnology into the field of reinforcement materials, the pre-stressed carbon board and supporting anchor system developed by the company have been well received by the industry.

Hummer reinforcement material product consultation: xxx-xxx-xxxx

Responsibilities Includes

|

Supply or provide the technology or service |

|---|---|

|

Provide technical training to Co-mender’s team and to the local Partners |

|

Update the team with new development |

|

Provide technical support during business development and execution stages |

|

Use our ComendX app to collaborate |

|

Use our ComendAIR to supevise the materials installation or technology implementation |

|

Join the Comenders Community |